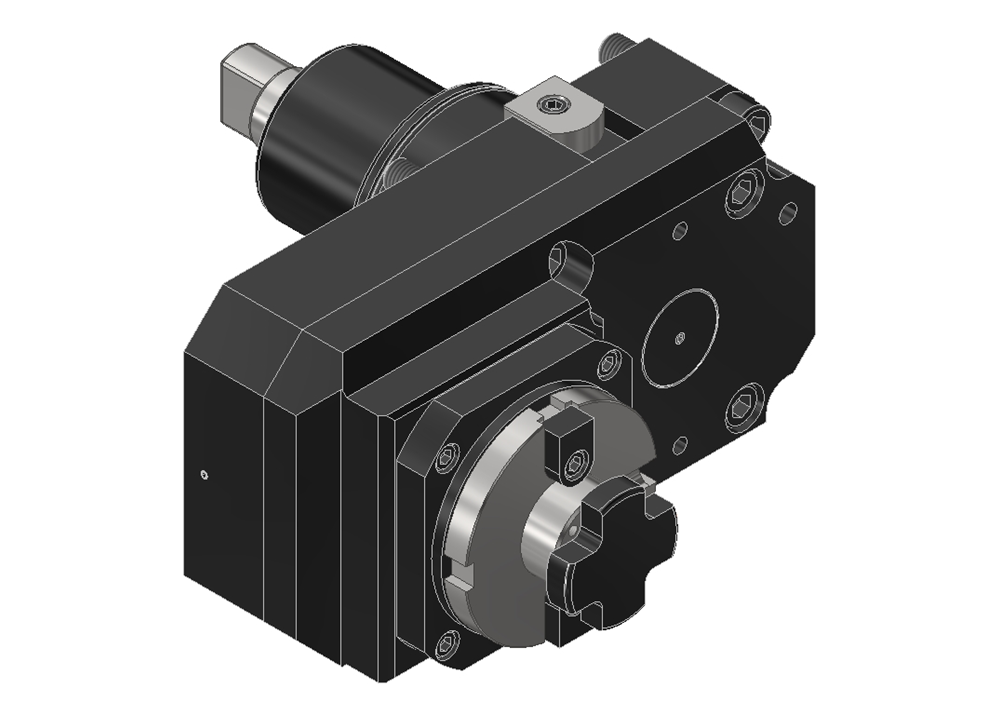

52.8538.1KR1809IKDI3X102 - Axial milling head offset, Arbor Ø 38.1, with tapered roller bearing, DIN 1809 drive, IC/EC Ceramic pmax = 70bar, i =3:1 direction of rotation inver., tool length,

Article number: 165145Axial milling head with offset axes

Premium class tool system for highest production efficiency - Made in Germany

Tapered roller bearings (KR) - extraordinarily loadable.

- Recommended for machining operations with high torques (e.g.: milling operations with large diameters, threading operations, interrupted cut machining)

- Increase of tool life

- Reduction of service intervals

- Simultaneous radial and axial loads can be easily absorbed

EWS.HPC-Line (IKC/IKD) - Sealing technology sets standards

- Ceramic based sealing elements

- 0 - 70 bar coolant pressure

- Dry running capability without restrictions

- Speeds up to 12,000/min

- Up to 60% reduced heat generation

- Long service life - low maintenance costs

- Seal kit for the latest generation of internal coolant supply systems

Загрузить PDF

| Total height (OAH) | 126.00 mm |

|---|---|

| Number of holders, workpiece side (CCONWS) | 1 |

| Max. torque (TQX) | 100.00 Nm |

| Max. rotational speed, input (RPMX) | 3000 min-1 |

| Transmission relation (TR) | 3:1 |

| Transmission torque, output drive 1 (DINH201) | 300.00 Nm |

| Shank size | BMT85 |

| Interface size | Fräserdorn Ø1,5″ (longitudinal and cross groove) |

| Coolant intake | Inner and outer cooling |

| Coupling | Surface coupling |

| Alignment system | BMT – keyway |

| Article number | 165145 |

|---|---|

| Product weight | 19.498 KG |