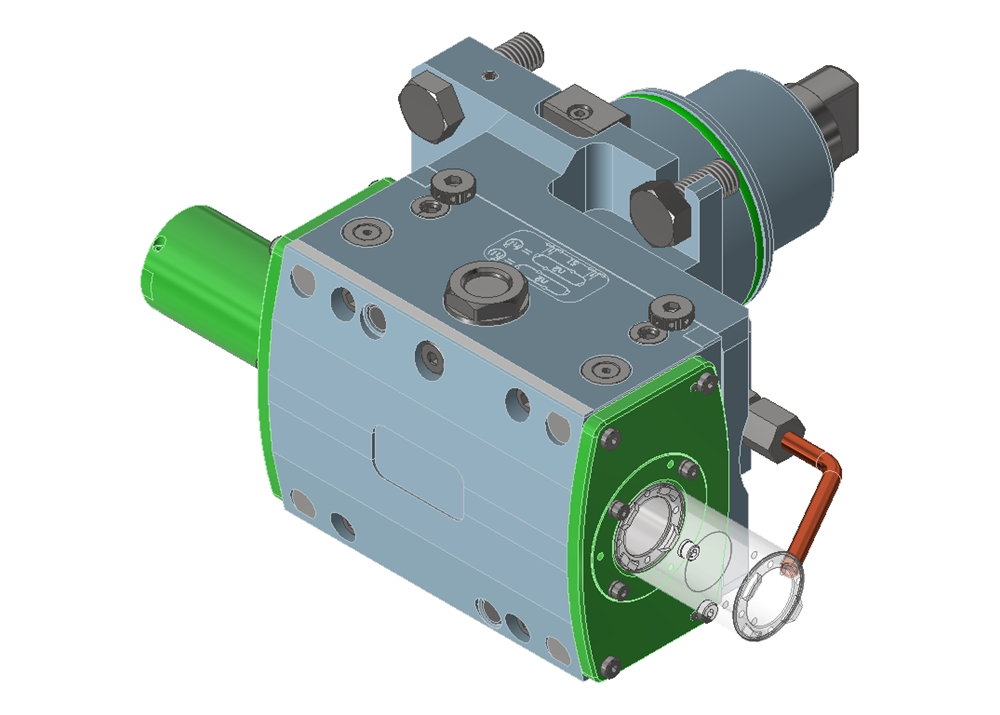

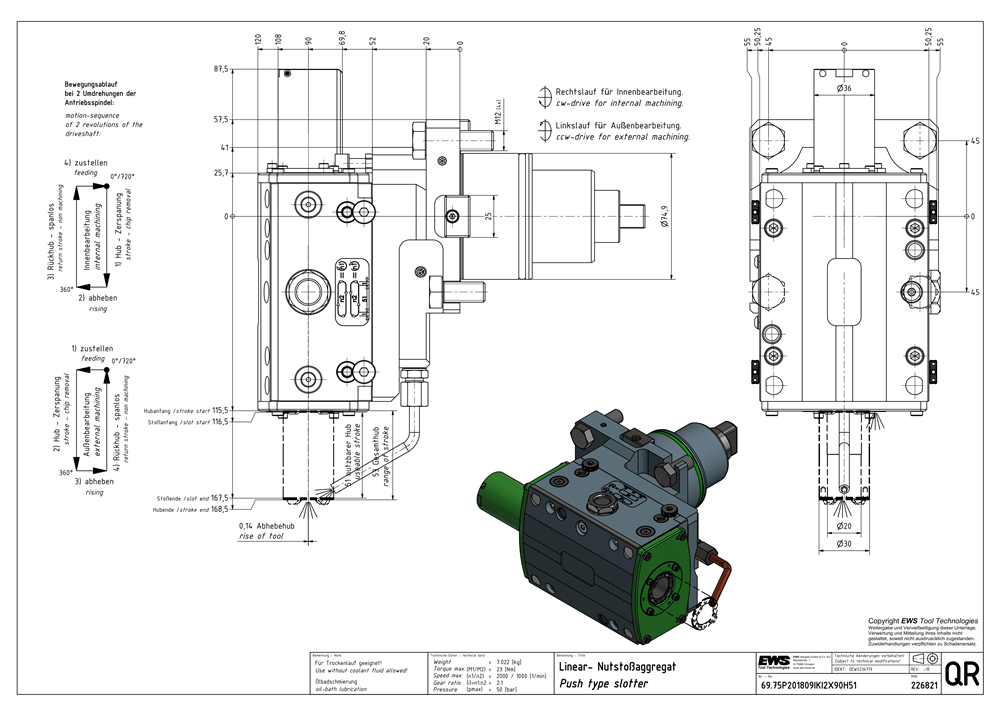

69.75P201809IKI2X90H51 - Push type slotter, prism adaption Ø20, DIN 1809 drive, Int. / ext. coolant pmax = 50bar, cw input for internal mach. i=2:1, tool length, stroke usable 51mm' total 53mm,

Article number: 226821EWS.Slot - Grooving in a new dimension.

With the grooving unit, internal and external splines can be manufactured completely and position-oriented. The unit is driven by the tool turret and one revolution always corresponds to a complete stroke. The speed of the spindle and the constant feed in X ranges, depending on the model, between 400 rpm - 1,500 rpm and 0.04 - 0.15mm/stroke.

- Economical production of inner and outer profiles

- Reduced setup times and costs due to complete machining in only one setup

- Up to 1,500 rpm

- Stroke length: 19mm - 53mm (see operating instructions for details)

- Useful length: 17mm - 51mm (details see operating instructions)

- Machine-friendly - No heavy components of the machine are moved for stock removal.

Premium class tooling system for highest production efficiency - Made in Germany.

Latest generation

- Internal & external cooling

- Ø30 prism holder (previously Weldon Ø16)

- Up to 1.500 1/min

- Groove width 10 mm

- Maintenance Recommendation:

- After 1 year or

- 750 operating hours or

- 25,000,000 double strokes

- Increasing wear on materials with:

- a tensile strength > 900 N/mm2

- a hardness > 270 HB or 28 HRC

- Cast materials

For further details on the product, handling instructions and specific manufacturing examples, please refer to the operating instructions, which can be downloaded under the Media tab.

Stroke length

- Stroke length: 53 mm

- Effective length: 51 mm

Загрузить PDF

| Number of holders, workpiece side (CCONWS) | 1 |

|---|---|

| Max. torque (TQX) | 0.00 Nm |

| Max. rotational speed, input (RPMX) | 2000 min-1 |

| Transmission relation (TR) | 2:1 |

| Transmission torque, output drive 1 (DINH201) | 23.00 Nm |

| Shank size | BMT75 |

| Coolant intake | Inner and outer cooling |

| Coupling | Surface coupling |

| Alignment system | BMT – keyway |

| Article number | 226821 |

|---|