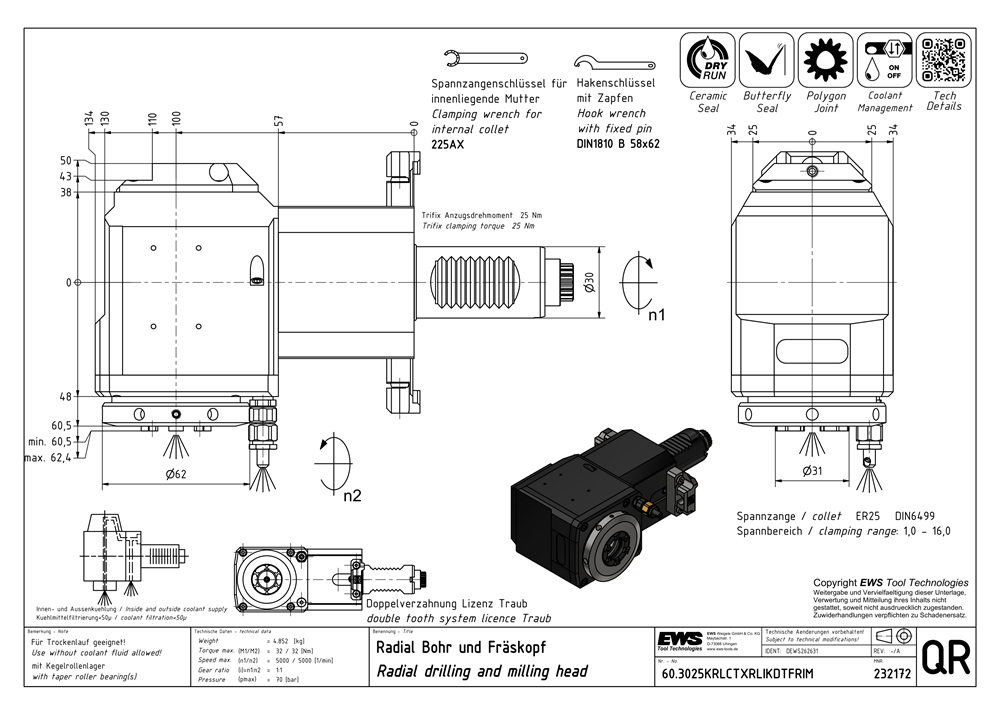

60.3025KRLCTXRLIKDTFRIM - Radial drilling and milling head, For collet 250 430E (ER25 Ø2-16), with tapered roller bearing, DIN 5480 drive, IC/EC Ceramic pmax = 70bar, i =1:1 direction of rotation inver., Trifix-alignment right, inside collet nut, Butterfly-Seal, cool.manag., polyg.

Article number: 232172Загрузить PDFRadial drilling and milling head

Premium class tool system for highest production efficiency - Made in Germany

Collet chuck ER25 DIN6499

- Clamping range Ø2-16

- For collet 250 430E

- When tightening the clamping nut, it is essential to counterhold the tool spindle.

- Failure to observe the counterholding may result in damage to the gearbox or drive coupling.

- Maximum tightening torque: 90 Nm

Tapered roller bearings (KR) - extraordinarily loadable.

- Recommended for machining operations with high torques (e.g.: milling operations with large diameters, threading operations, interrupted cut machining)

- Increase of tool life

- Reduction of service intervals

- Simultaneous radial and axial loads can be easily absorbed

Double toothing (Traub license)

- VDI shank double toothed.

- Tool holder can be rotated 180°.

- Note: Rotatability may be restricted by alignment systems (e.g. Trifix).

EWS.HPC-Line (IKC/IKD) - Sealing technology sets standards

- Ceramic based sealing elements

- 0 - 70 bar coolant pressure

- Dry running capability without restrictions

- Speeds up to 12,000/min

- Up to 60% reduced heat generation

- Long service life - low maintenance costs

- Seal kit for the latest generation of internal coolant supply systems

Trifix© (TF) alignment system

- Tool completely preset

- Faster setup of your machine

- Repeatability < 6µm at 200mm throat depth

- Positioning accuracy of 0.01mm from one station to another

Polygonal shaft hub connection

The latest series of our tool systems are equipped with polygonal shaft hub connections. Compared to tool holders with key connections, there are clear technological advantages:

- Reduced vibrations of the tool spindle

- Significantly increased power transmission

- Less gear backlash

EWS.Butterfly-Seal - sealing technology in a class of its own

- Speed-related lift-off function of the sealing element

- No friction-induced running-in of the spindle

- Reduced mold heating by up to 50%

- Effective protection against cooling emulsion and dirt particles

- Lower repair costs

EWS.Coolant Management - simply clever

- Opening and closing of external cooling with just one turn

- Coolant flow adjustable

- Time saving due to easy handling

| Functional length (LF) | 100.00 mm |

|---|---|

| Total height (OAH) | 68.00 mm |

| Number of holders, workpiece side (CCONWS) | 1 |

| Max. torque (TQX) | 32.00 Nm |

| Max. rotational speed, input (RPMX) | 5000 min-1 |

| Transmission relation (TR) | 1:1 |

| Transmission torque, output drive 1 (DINH201) | 32.00 Nm |

| Shank size | VDI30 |

| Interface size | Collet ER25 |

| Coolant intake | Inner and outer cooling |

| Coupling | DIN 5480 |

| Alignment system | Trifix |

| Article number | 232172 |

|---|