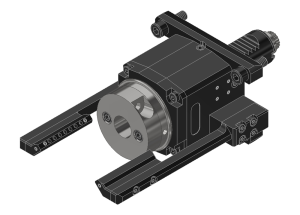

Артикул: 231915

Axial drilling and milling head

Premium class tool system for highest production efficiency — Made in Germany

Hyrodehn interface

- High precision clamping

- Optimum concentricity of the tool cutting edge

- Good damping against vibrations and chatter

- Reducing sleeves available to adjust the clamping diameter

- Clamping of the cutting edge by only one screw

- No additional fixture necessary

- Observe tightening torque

Tapered roller bearings (KR) — extraordinarily loadable.

- Recommended for machining operations with high torques (e.g.: milling operations with large diameters, threading operations, interrupted cut machining)

- Increase of tool life

- Reduction of service intervals

- Simultaneous radial and axial loads can be easily absorbed

EWS.Butterfly-Seal — sealing technology in a class of its own

- Speed-related lift-off function of the sealing element

- No friction-induced running-in of the spindle

- Reduced mold heating by up to 50%

- Effective protection against cooling emulsion and dirt particles

- Lower repair costs

EWS.Coolant Management — simply clever

- Opening and closing of external cooling with just one turn

- Coolant flow adjustable

- Time saving due to easy handling

| Total height (OAH) | 68.00 mm |

|---|---|

| Number of holders, workpiece side (CCONWS) | 1 |

| Max. torque (TQX) | 32.00 Nm |

| Max. rotational speed, input (RPMX) | 5000 min-1 |

| Transmission relation (TR) | 1:1 |

| Transmission torque, output drive 1 (DINH201) | 32.00 Nm |

| Shank size | VDI30 Proline |

| Interface size | Hydraulic chuck Ø 20.0 |

| Coolant intake | Outer cooling |

| Coupling | DIN 5480 |