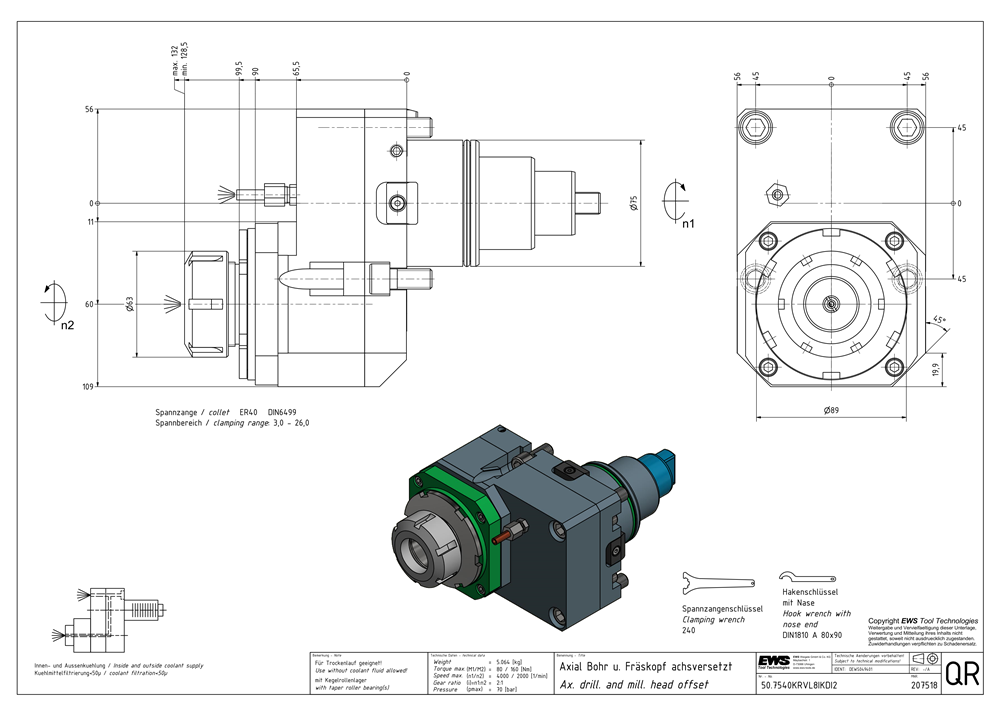

50.7540KRVL8IKDI2 - Ax. drill. and mill. head offset, For collet 400 472E (ER40 Ø4-26), with tapered roller bearing, Similar to DIN 1809 drive, IC/EC Ceramic pmax = 70bar, i = 2:1 same rotating direction,

Article number: 207518Axial drilling and milling head with offset axes

Premium class tooling system for highest production efficiency - Made in Germany

Collet chuck ER40 DIN6499

- Clamping range Ø4-26

- For collet 400 472E

- When tightening the clamping nut, it is essential to counterhold the tool spindle.

- Failure to observe the counterholding may result in damage to the gearbox or drive coupling.

- Maximum tightening torque: 160 Nm

Tapered roller bearings (KR) - extraordinarily loadable.

- Recommended for machining operations with high torques (e.g.: milling operations with large diameters, threading operations, interrupted cut machining)

- Increase of tool life

- Reduction of service intervals

- Simultaneous radial and axial loads can be easily absorbed

EWS.HPC-Line (IKC/IKD) - Sealing technology sets standards

- Ceramic based sealing elements

- 0 - 70 bar coolant pressure

- Dry running capability without restrictions

- Speeds up to 12,000/min

- Up to 60% reduced heat generation

- Long service life - low maintenance costs

- Seal kit for the latest generation of internal coolant supply systems

Загрузить PDF

| Number of holders, workpiece side (CCONWS) | 1 |

|---|---|

| Max. torque (TQX) | 80.00 Nm |

| Max. rotational speed, input (RPMX) | 4000 min-1 |

| Transmission relation (TR) | 2:1 |

| Transmission torque, output drive 1 (DINH201) | 160.00 Nm |

| Shank size | BMT75 |

| Interface size | ER40 |

| Coolant intake | Inner and outer cooling |

| Coupling | Surface coupling |

| Alignment system | BMT – keyway |

| Article number | 207518 |

|---|---|

| Product weight | 5.064 KG |